Flat roof caulking plays a critical role in protecting commercial buildings in Bozeman, MT, where temperature swings, snow loads, wind, and intense sun exposure all place added stress on roofing systems. For building owners, understanding what flat roof caulking can and cannot do is essential for preventing leaks, managing maintenance costs, and extending roof life.

At Flag Ship Foam & Coatings, flat roof caulking is approached as a precision maintenance task, not a quick fix. To learn more, call 208-946-3031 and speak with an expert today.

Flat Roof Caulking: Benefits, Limits, and Best Practices

When applied correctly and in the right situations, caulking helps seal vulnerable areas and reduce water intrusion. When relied on incorrectly, it can delay necessary repairs and create bigger problems down the line.

What Flat Roof Caulking Does on Commercial Roofs

Flat roof caulking is used to seal small gaps, joints, and transition points where roofing materials meet. On commercial buildings, these areas are often the first places where water finds a way in. Caulking creates a flexible barrier that moves with the roof as it expands and contracts.

Rather than sealing the entire roof surface, caulking is focused on high-risk areas such as flashing seams, penetrations, termination points, and joints around equipment. Its job is to reinforce these details and prevent moisture from entering the roof assembly.

Key Benefits of Proper Flat Roof Caulking

When done correctly, flat roof caulking offers several important benefits for commercial building owners:

- Reduces the risk of leaks caused by minor separations or aging materials

- Protects insulation and decking from moisture damage

- Slows deterioration caused by freeze-thaw cycles common in Montana

- Supports overall roof performance as part of a maintenance plan

- Helps address small issues before they become major repairs

Caulking is especially valuable when combined with regular roof inspections. Catching sealant failure early allows for targeted repairs instead of costly emergency work.

The Limits of Flat Roof Caulking

While caulking is an effective maintenance tool, it has clear limits. It is not designed to solve structural issues, widespread membrane failure, or long-term water intrusion. Applying more sealant over damaged materials may temporarily stop visible leaks but often traps moisture below the surface.

Common situations where caulking alone is not sufficient include:

- Saturated insulation beneath the membrane

- Large membrane splits or seam failure

- Ongoing ponding water problems

- Aging roofs nearing the end of their service life

Understanding these limits helps building owners avoid relying on short-term fixes that lead to larger repair costs later.

Common Areas Where Flat Roof Caulking Is Applied

Commercial flat roofs have multiple details that depend on properly maintained sealant. These include:

- Parapet walls and roof edges

- Flashing transitions

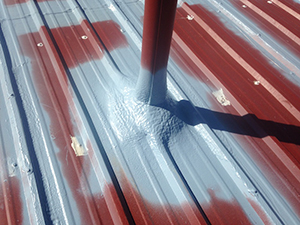

- HVAC units, vents, and pipe penetrations

- Skylights and equipment curbs

- Drains and scuppers

Each area experiences movement, vibration, and exposure differently. Applying the right sealant in the right location is just as important as the application itself.

Best Practices for Flat Roof Caulking

Successful flat roof caulking starts with preparation. Surfaces must be clean, dry, and stable before sealant is applied. Using the correct sealant type that is compatible with the roof system is also critical.

Best practices include:

- Removing failed or deteriorated sealant before reapplication

- Using commercial-grade sealants designed for roof movement

- Applying sealant in appropriate thickness for flexibility and durability

- Avoiding over-caulking, which can restrict movement and crack over time

Professional installation ensures that caulking supports the roof instead of creating new stress points.

When to Call a Commercial Roofing Professional

If leaks persist, caulking failures appear repeatedly, or water damage is visible inside the building, a professional inspection is essential. Flat roof caulking works best as part of a broader roof maintenance or restoration strategy.

Flag Ship Foam & Coatings works with commercial building owners in Bozeman, MT to evaluate roof conditions, identify the true source of leaks, and recommend solutions that protect the building long term rather than just addressing symptoms.

Flat Roof Caulking Professionals

If your commercial flat roof shows signs of aging sealant, leaks, or recurring moisture issues, a professional evaluation can help you decide whether caulking is appropriate or if additional repairs are needed. Flag Ship Foam & Coatings provides expert flat roof inspections and maintenance solutions designed for Montana’s demanding climate. Call us today at 208-946-3031 and schedule your consultation.

FAQ

How often should flat roof caulking be inspected on commercial buildings?

Flat roof caulking should be inspected at least once a year and after severe weather events to catch early signs of failure.

Can flat roof caulking be applied in cold weather?

Some sealants are formulated for cooler temperatures, but proper surface conditions and product selection are critical for long-term performance.

Is flat roof caulking covered under roof warranties?

Warranty coverage depends on the roof system and application method. Improper caulking can void warranties, which is why professional evaluation is important.